Dry Ager South Africa imports a variety of equipment options to cater for the South African market and bring you a solution that will best suit your space, the amount of meat you would like to mature and all this with the SmartAging® technology from Germany.

PART 13: Overview of all Dry Ager units available in South Africa: Discover Dry Ager Equipment with Chris Fourie

We have a wide range of solutions available to meet your Dry Aging needs!

There is a few options to choose from in the Dry Ager range of products when selecting the perfect solution for your needs…

The DRY AGER® Premium S line is the world’s only aging refrigerator series with an active UVC sterilization box that completely sterilizes the entire air mass in the Aging Cabinet.

The new DRY AGER® Aging Cabinet generation guarantees you unique aging results, simply and easily with SmartAging® and perameters are as precise as Swiss clockwork – only from Germany.

And all this without a water connection or tank, thanks to HumiControl®.

The option of fully automatic with the SmartAging® programs or self-adjusted in manual mode is your choice.

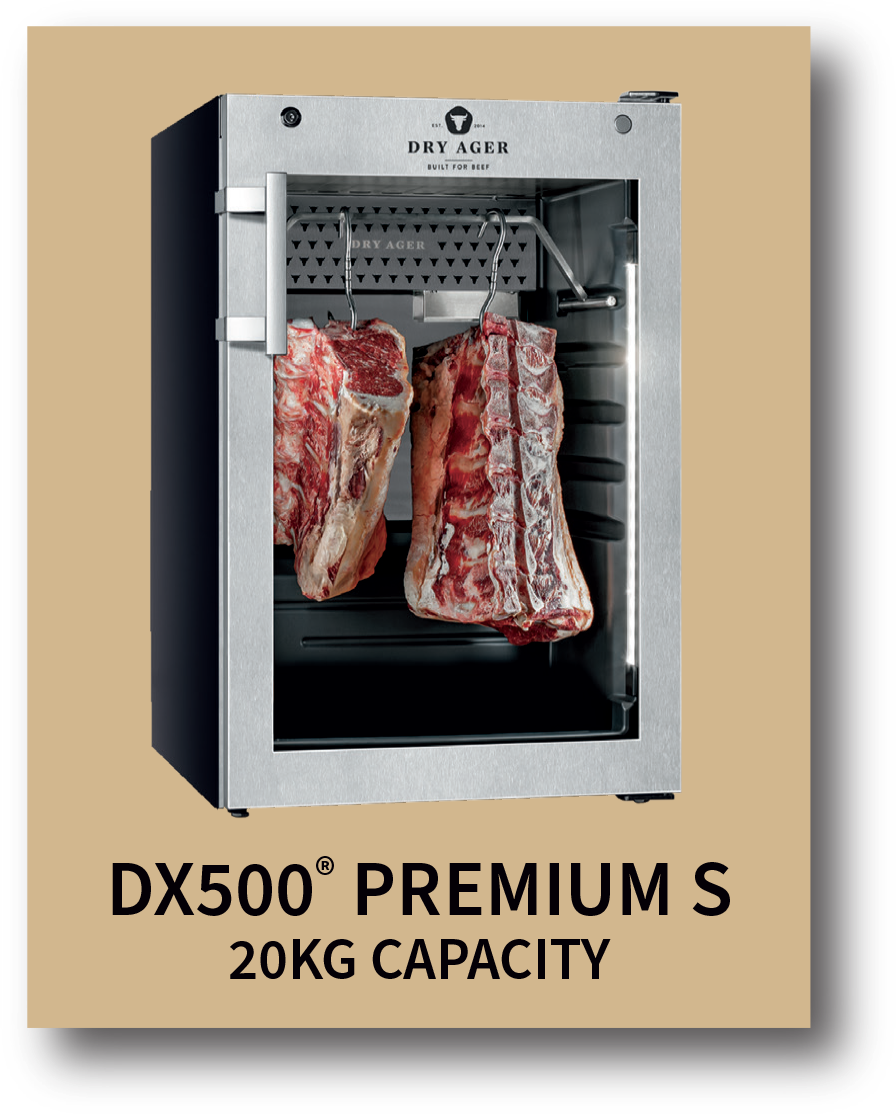

DX500 Premium S...

It’s so compact.

but just as capable.

This is the smallest cabinet available. But don’t be discouraged by size, as this ‘little one’ from DRY AGER® packs a punch just like the big one and comes with new SmartAging® Technology. It integrates perfectly into your kitchen or sales area, and whets the appetite for perfectly aged food. The compact unit can be free-standing or easily integrated into the wall, both at home or at work.

Up to 20kg of meat can be aged in the device at once from meat to charcuterie, or cheese to fish, the DRY AGER® DX 500 Premium S is ready for the whole spectrum of food products.

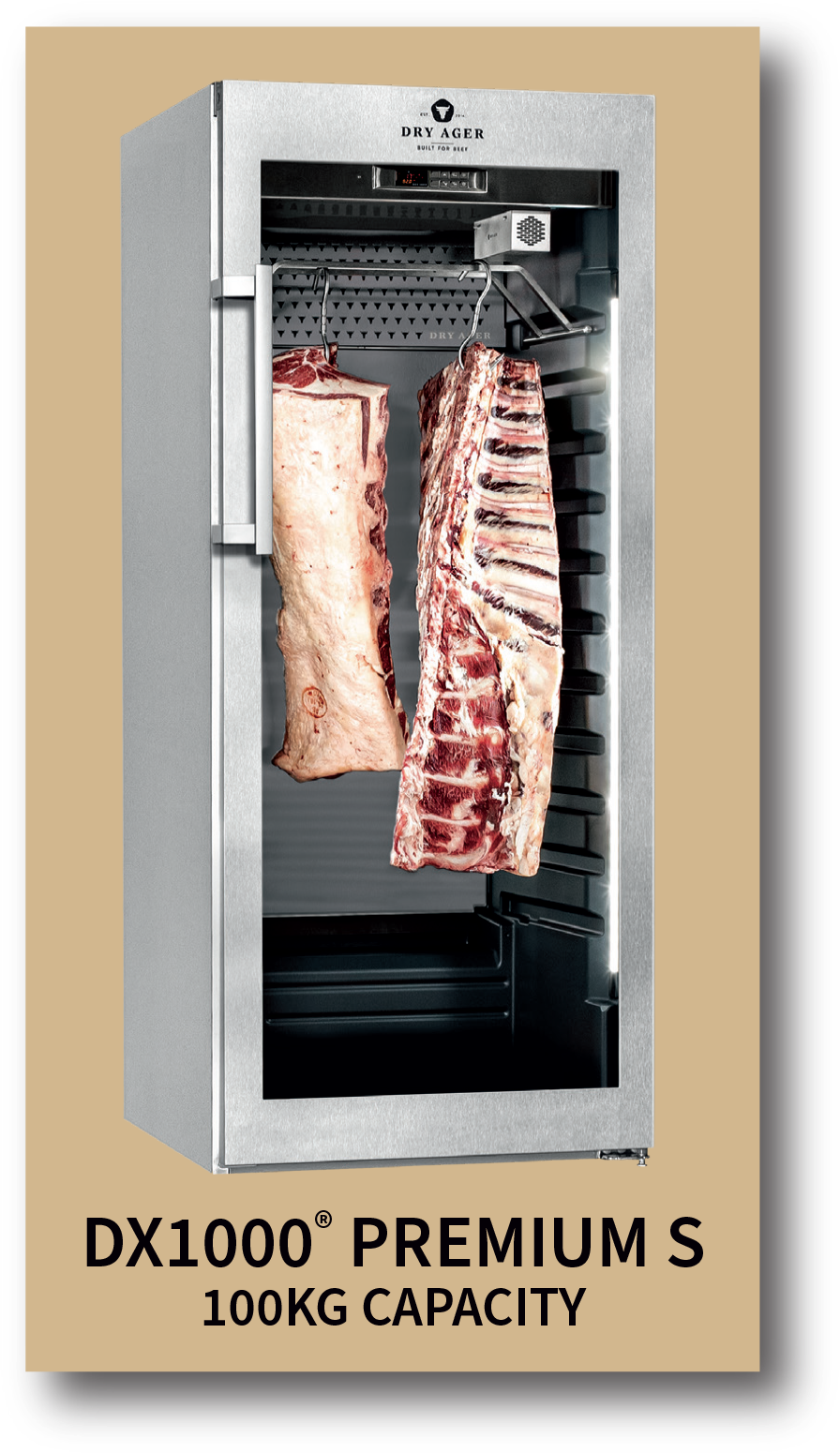

DX1000 Premium S...

More room for good taste.

With the best quality.

This unit is our best seller and allows up to 100kg to be aged simultaneously.

Yes, its so big that you can get creative. Whether with venison, sausage, meat, cheese, ham, or more: Now you can age like a pro thanks to SmartAging®. This cabinet is free-standingor can be integrated into the wall, it’s a real eye-catcher in any environment, and with absolute added value.

You have maximum flexibility with the DRY AGER DX 1000 Premium S and it’s capacity of 100kg an aging cycle really pays off.

Dry aging on an even larger scale.

Easy to retrofit.

The DX8000 for up to 24m3 capacity

A technically fully equipped Dry Aging chamber can be retrofitted to an existing cold room in just a few simple steps.

The DRY AGER® Dry Aging Production Units are placed on top of your cold room as a plug-in ready ceiling solution or integrated into your cooling infrastructure as a split-unit.

For you, this means absolute flexibility with full Dry Aging functionality. HumiControl®, DX AirReg®, and the integrated UVC sterilization system ensure an optimal microclimate for aging venison, meat, sausage, ham, cheese or fish.

All other foods or products that require a special climate can also be stored professionally thanks to this technology.

For those who want to physically separate the exterior unit from the evaporator in the cell due to lack of space, wasted heat, or noise, the Split-System or the evaporator system have all the options. The systems are individually tailored to your needs..

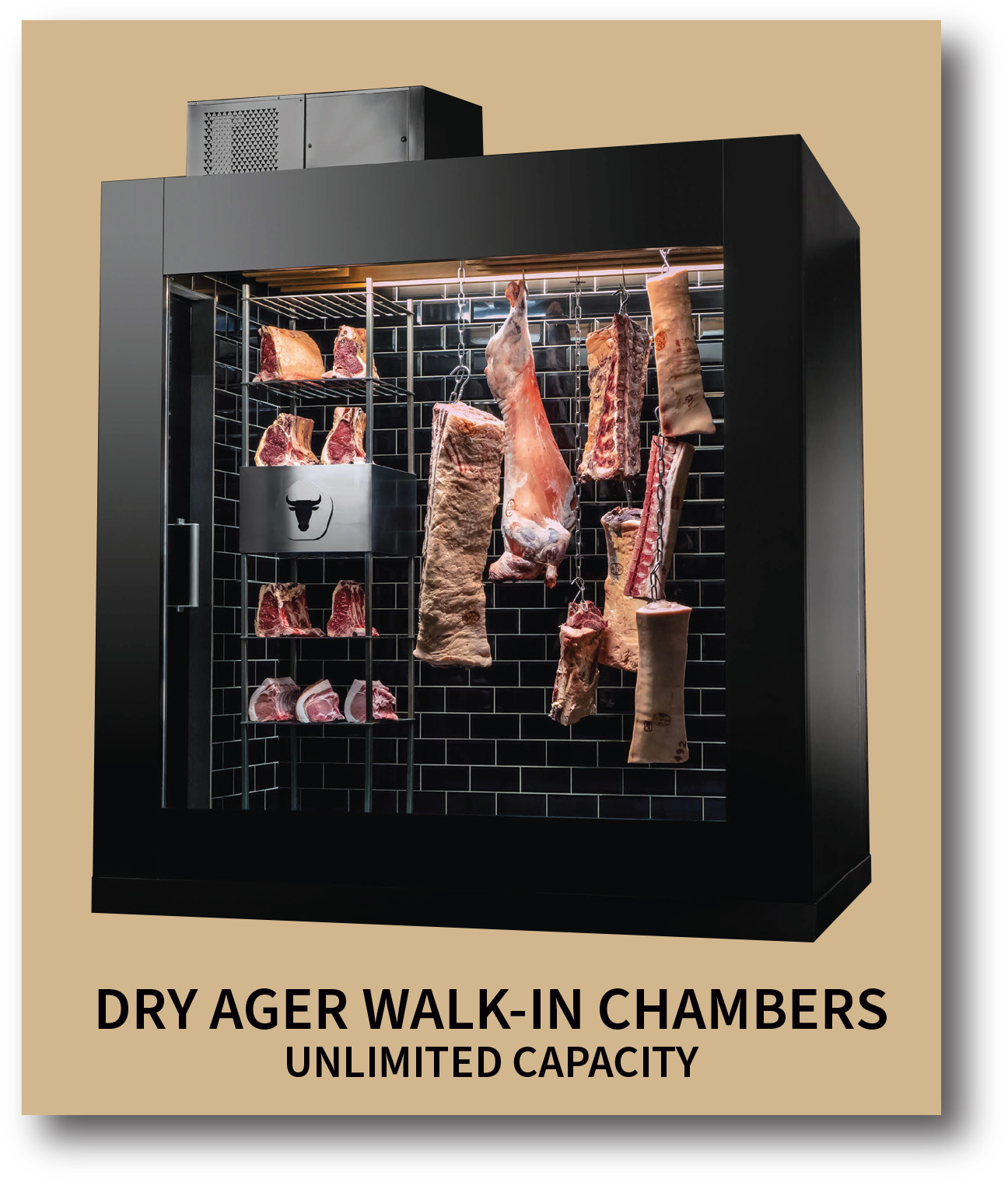

Dry Ager Walk-in Chambers.

The ideal solution when you thinking big!

This option is exactly as big as you need. The Dry Aging Walk-in Chambers turn your area into a full Dry Aging experience room.

In order to achieve this goal, your Dry Aging walk-in chamber is planned step by step together with an expert from DRY AGER® and adapted to meet your needs.

Each Dry Aging Walk-in Chamber is equipped with all the proprietary Dry Aging technologies, includinng: HumiControl®, DX AirReg®, and the UVC sterilization unit comes standard.

You get to customise the size, shape, material build, colour, interior design, distribution cooling system, lighting, and much more with a walk-in chambef. This is how you create the ultimate shopping experience for your customers.

Keep a look out for Part 14 on 6 December 2023 and discover why it’s best to use a Dry Ager solution for your maturation process with Chris Fourie

Copyright 2023 | All Rights Reserved | Powered by WILD & JAG / GAME & HUNT