PART 10: Discover Our Easy To Retrofit Dry Ager ProductionUnits With Chris Fourie

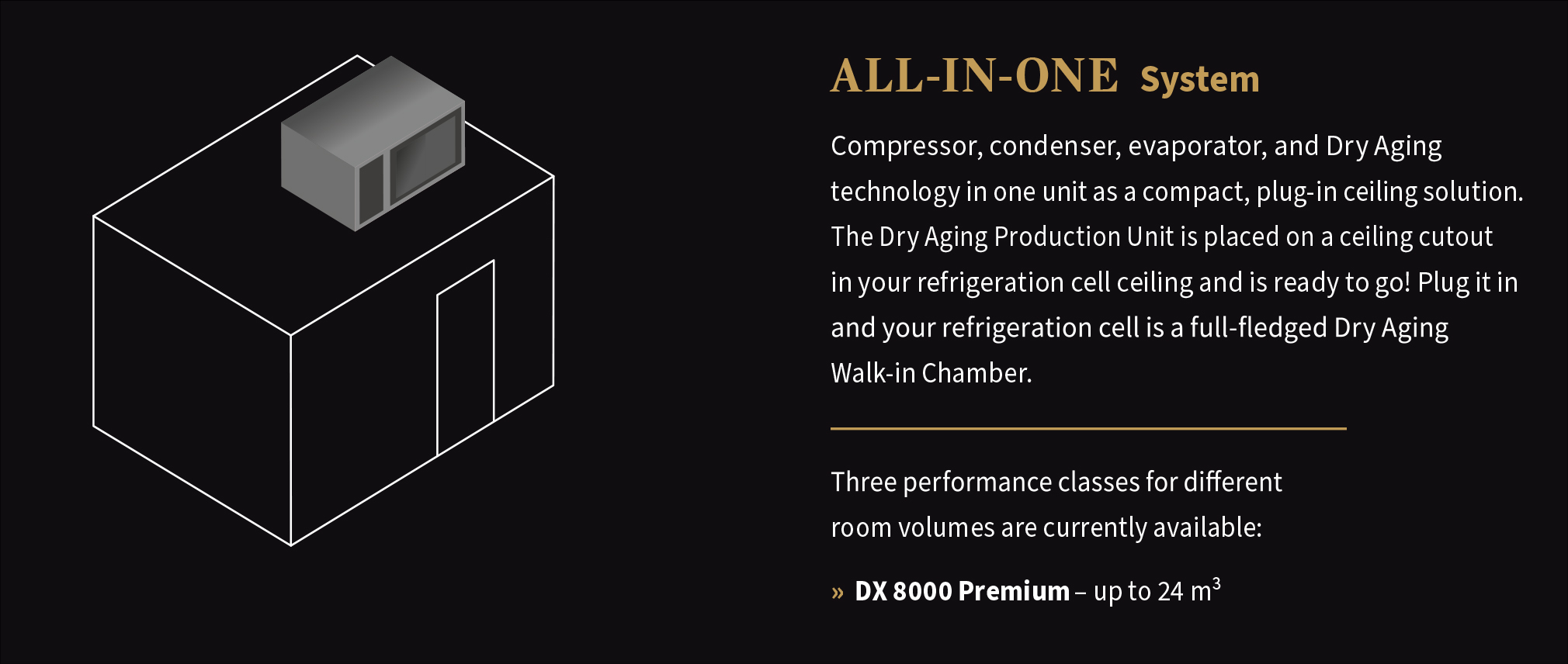

With these super-efficient plug & play Dry Ager® Production cooling units, you can turn your existing space into a fabulous dry aging space for your venison. Yes! you can now retrofit any existing walk-in larder or cold room. All you have to do is make an opening in the ceiling, place the production unit on top and plug it in – it’s that simple!

Dry age on a large scale by turning your existing cold room into a Dry Ager cold room – easy to retrofit – with our Dry Aging Production Units

The all-in-one system includes all the related components and can be installed as a compact ceiling solution onto your current cold room depending on the cell size or conditions on site. We are available to guide you into the perfect retrofitting solution. You can trust our expert advice to find a solution to give you absolute flexibility with the full Dry Ager functionality.

Our DX 8000 PREMIUM unit allows for up to 24 m³ capacity. Should your cold room be bigger we can use several DRY AGER™ production units simultaneously to achieve ultimate maximum potential for your dry aging meat maturation results.

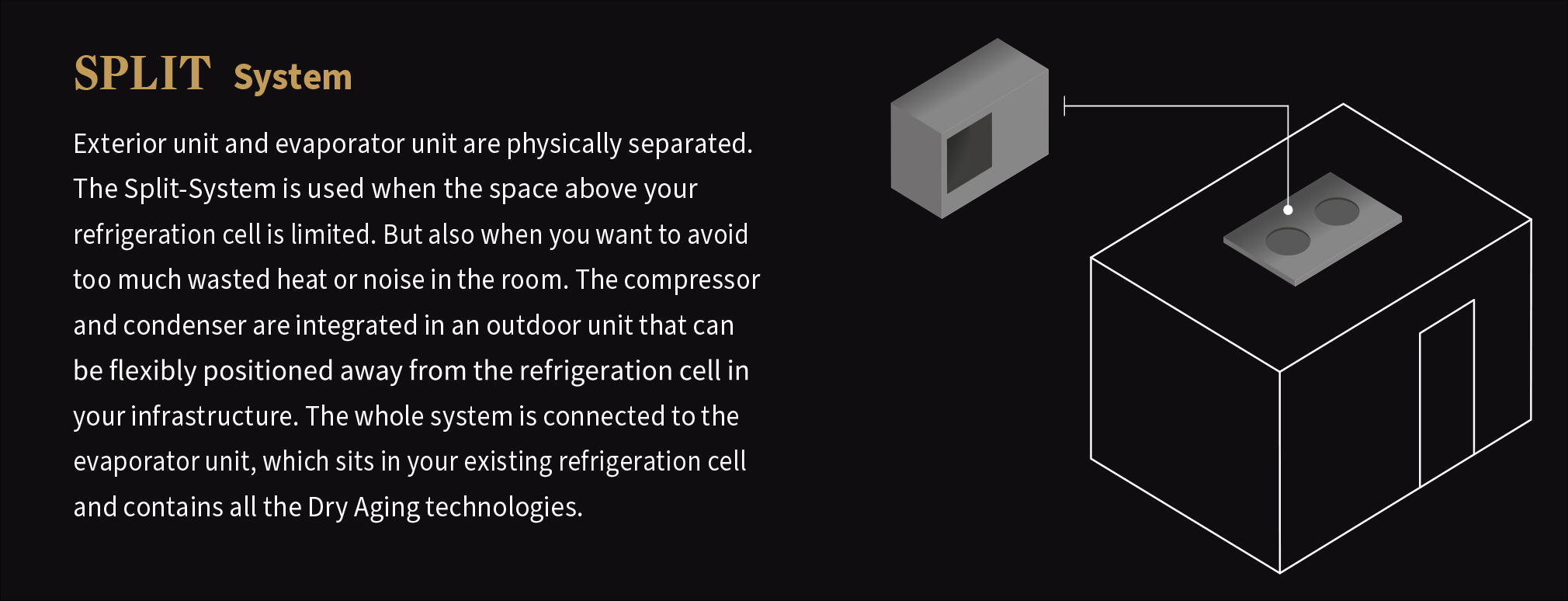

If you feel due to lack of space, waste heat, or are concerned about noise and want to physically separate the exterior unit from the evaporator in the cell, then the Split-System or the Evaporator System are options to be considered. All our systems are individually tailored to your needs and adapt to almost all performance sizes.

All the technical Dry Ager features come standard on the models offered. You are assured of exact temperature control from 0°C to +25°C, and the humidity is also controlled accurately through the integrated HumiControl™ system, which can be set electronically between 60 and 90 %. This guarantees results aswell as product safety, together with the DX AirReg™ system, a perfect micro-climate with an ideal air-flow and continuous sterilisation throughout the cool room.

You are ensured maximum reliability and 100% reproducible aging results at all times.

Expect the best product… 100% hand-made in Germany.

DRY AGER™ PRODUCTION UNITS As individual as your requirements...

Our Dry Ager® production units are imported from Germany and supplied as plug-in solutions with all the technical features of a fully equipped dry aging production facility.

The integrated UVC sterilization ensures maximum safety and guarantees perfect dry aging results. Dry aging venison, beef, pork, salami, ham, cheese and more can be produced with unrivalled flexibility.

We can also proudly say that after many tests we have implemented, it has been found that weight loss is at a minimal – our results show a maximum of 10% weight is lost after 4 weeks of dry aging meat on the bone.

An added benefit is that this retrofit does not need a water connection. And of course, the cold room can still be used for normal refrigeration and storage of food.

For more information contact Chris Fourie on +27 64 684 9666 or email chris@dryagersa.co.za

Keep a look out for Part 11 on 25 October 2023 – Venison carcass composition and butcher cuts

Copyright 2023 | All Rights Reserved | Powered by WILD & JAG / GAME & HUNT